BRAVILOR

Bravilor invests in 6 more Bramidan balers

The company’s X25 HD has prompted the company to invest in 6 more balers, aiming to maximize optimization and productivity even further.

From Challenges

Challenges

- Hygiene is important

- Lots of cardboard in assembly area

- Cardboard is the main waste material

To Benefits

Benefits

- Improved productivity

- Neat and tidy production area

- Better internal logistics

With Bramidan

Machines chosen

The X-series at Bravilor Bonamat tidies up and saves time

Neat and tidy production area

Cardboard was and is the main waste flow at Bravilor Bonamat. The first baler, a X25 HD from the X-series, was therefore used for cardboard. This brought an immediate end to the untidy looking wire mesh containers that had been used previously. The baler was so popular that short afterwards the model X10 HD was introduced for soft plastic, as this is also a significant waste flow for the beverage machine manufacturer.

Over the years, each time there was a need for it, a small or a large machine was added here and there in the company and in this way the current ‘baler park’ of six machines was built up.

Over the years, each time there was a need for it, a small or a large machine was added here and there in the company and in this way the current ‘baler park’ of six machines was built up.

Less work – and it’s even fun

Better internal logistics

Bramidan was the obvious choice right from the start. “The compactness of the machines appeals to us”, explains Kees. “It’s not a huge object to look at. And as none of the cylinders stick out it’s a closed unit. It just looks good.”

For the assembly personnel the balers mean less work, as they do not have to cut and flatten the boxes. The whole cardboard box fits through the filling opening. Even the office staff at Bravilor Bonamat think it is fun and take their boxes to the machines. When the baler chamber is full, someone presses the button and the machine is ready again for the next load of waste. Soft plastic is collected in waste bags. When the bags are full, a knot is put in the top and the whole thing goes into the baler.

For the assembly personnel the balers mean less work, as they do not have to cut and flatten the boxes. The whole cardboard box fits through the filling opening. Even the office staff at Bravilor Bonamat think it is fun and take their boxes to the machines. When the baler chamber is full, someone presses the button and the machine is ready again for the next load of waste. Soft plastic is collected in waste bags. When the bags are full, a knot is put in the top and the whole thing goes into the baler.

What matters is production

Improved productivity

Prior to the purchase of the first X25 HD the waste was collected every other day. This became less frequent with the purchase of each extra baler.

Kees van Muiswinkel has never calculated if Bravilor Bonamat makes money from the compacted cardboard and soft plastic. “It depends on the price of recycled materials, which of course varies all the time. For us the only thing that matters is that our employees need not spend a lot of time on handling waste. So that they can get on with what matters; production.”

Kees van Muiswinkel has never calculated if Bravilor Bonamat makes money from the compacted cardboard and soft plastic. “It depends on the price of recycled materials, which of course varies all the time. For us the only thing that matters is that our employees need not spend a lot of time on handling waste. So that they can get on with what matters; production.”

You have to manage your waste flows just as efficiently as your parts flow.

Kees van Muiswinkel

Technical Manager, Bravilor Bonamat

FACTS ABOUT

BRAVILOR

Popular within

Industry and production

VERTICAL BALER

Baler B4

The B4 is packed with nice extra features that you don’t find in other small balers. Enjoy high compaction and automatic bale ejection.

VERTICAL BALER

Baler B4 Textile

Compact clothes and textiles into transport friendly bales with no risk of ripping.

VERTICAL BALER

Baler B5 Wide

The B5 Wide is characterised by a wide filling opening of 1 metre. It is specially designed to handle bulky materials.

VERTICAL BALER

Baler X10

A compact baler with high capacity and an unmatched 10-tonne press force. Low height and small footprint make it easy to install.

VERTICAL BALER

Baler B20

A flexible baler for cardboard, paper, and soft plastic. A wide filling opening for large boxes and retainers to prevent in-chamber material expansion.

VERTICAL BALER

Baler X25

The X25 is equipped with long stroke cross cylinders for a stable compression and superior press force. Expect a high bale weight.

VERTICAL BALER

Baler X25 Galvanized

Specially developed for wet or demanding environments. Hot-dip galvanized to withstand severe circumstances – indoors or outdoors.

VERTICAL BALER

Baler X30 LP

The X30 LP has a low overall height in combination with a high compaction force.

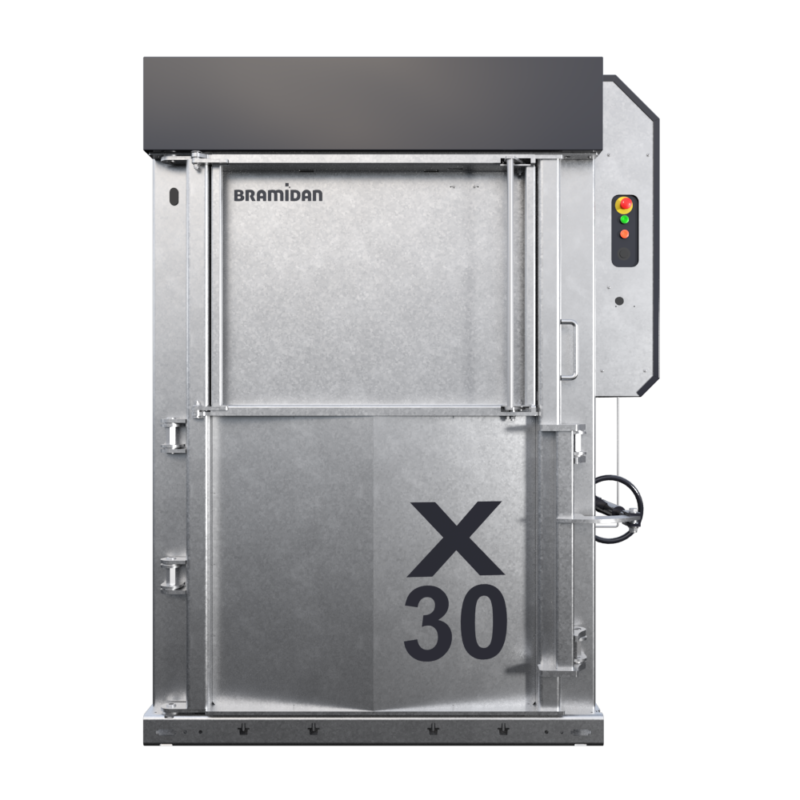

VERTICAL BALER

Baler X30

A baler for many types of materials. Bulky boxes and expandable plastic are no problem for this high capacity and large feed baler.

VERTICAL BALER

Baler X30 Galvanized

Suitable for wet waste or waste with residual liquids. Easy to wash down if needed. Cross cylinder compaction tackles all types of waste material.

VERTICAL BALER

Baler B30 Wide

Enjoy easy loading with the extra wide filling opening. There is no need to fold even large cardboard boxes.

VERTICAL BALER

Baler X40 Wide

The X40 Wide is a low profile baler with a wide filling opening, high press force, and heavy duty construction.

VERTICAL BALER

Baler X50

The X50 is designed for users, who demand a superior heavy-duty machine with focus on operational reliability and safety.

VERTICAL BALER

Baler X50 Galvanized

Our unique range of galvanized balers are designed for wet or demanding environments. Also suitable to be installed outdoors – they can withstand anything the weather throws at them.

VERTICAL BALER

Baler B50 XL SD

The B50 XL with a semi-automatic Sliding Door is an extra-large baler. Enjoy easy loading due to the wide door and deep chamber. Stack bales 2 and 2 for optimal truckloads.