SAUER-DANFOSS

Production skyrockets with the addition of 10 Bramidan balers

Danish hydraulics manufacturer, Sauer-Danfoss, saw a notable production boost after installing 10 balers from Bramidan. The remarkable increase has led to plans for investing in 10 more balers.

From Challenges

Challenges

- Strict safety requirements

- Implementation of LEAN principles

- Immediate removal of waste from production lines

To Benefits

Benefits

- More space in production

- Fewer waste collections

- Increased safety

With Bramidan

Machines chosen

Vertical Balers

Baler X25

Balers boost productivity at Sauer-Danfoss

Immediate removal of waste from production lines

The Danish company Sauer-Danfoss is a global producer of hydraulic and electronic systems for mobile equipment, such as forklifts, tractors, cranes and contractor equipment.

At the factory in Nordborg components and spareparts from sub-suppliers worldwide are unpacked and assembled in the fitting area. The components are delivered, safely wrapped in cardboard, paper and plastic to protect the contents against rust. When repacked for use at the assembly line, all packaging must be removed immediately. Therefore the waste is compacted in Bramidan balers.

At the factory in Nordborg components and spareparts from sub-suppliers worldwide are unpacked and assembled in the fitting area. The components are delivered, safely wrapped in cardboard, paper and plastic to protect the contents against rust. When repacked for use at the assembly line, all packaging must be removed immediately. Therefore the waste is compacted in Bramidan balers.

Efficient workflow

Implementation of LEAN principles

Four years ago Sauer-Danfoss introduced the balers, when the company reorganized the working routines in the factory, using LEAN principles.

“The balers had to fulfil four main purposes. We wanted to increase the production area; to have less waste collections, no containers at the exits, and finally we wanted to increase safety in the production area”, says Henning Sørensen, strategic purchaser at Sauer-Danfoss.

“The balers had to fulfil four main purposes. We wanted to increase the production area; to have less waste collections, no containers at the exits, and finally we wanted to increase safety in the production area”, says Henning Sørensen, strategic purchaser at Sauer-Danfoss.

Secure with leasing

Increased safety

Four of the 10 balers were installed in the section, which manufactures control units. The balers are placed strategically in the fitting areas where all received parts are unpacked. Placing the balers so close to the waste source, saves time in the daily routines. “We used to have containers standing outside, and the employees had to go outside with waste. Now they throw it directly into a baler. The compacted bale is picked up by a forklift, which takes it away for recycling,” tells Henning Sørensen.

All balers are leased with a full service agreement. This means that adjustments, repairs and maintenance are done automatically. A technician from Bramidan visits the company once a year and carries out a service check on all the machines. Sauer-Danfoss knows the monthly costs, and there are no additional invoices.

All balers are leased with a full service agreement. This means that adjustments, repairs and maintenance are done automatically. A technician from Bramidan visits the company once a year and carries out a service check on all the machines. Sauer-Danfoss knows the monthly costs, and there are no additional invoices.

FACTS ABOUT

SAUER-DANFOSS

The Danish company Sauer-Danfoss is a global producer of hydraulic and electronic systems for mobile equipment, such as forklifts, tractors, cranes and contractor equipment. At the factory in Nordborg components and spareparts from sub-suppliers worldwide are unpacked and assembled in the fitting area. The company has approx. 7500 employees worldwide.

Popular within

Industry and production

VERTICAL BALER

Baler B4

The B4 is packed with nice extra features that you don’t find in other small balers. Enjoy high compaction and automatic bale ejection.

VERTICAL BALER

Baler B4 Textile

Compact clothes and textiles into transport friendly bales with no risk of ripping.

VERTICAL BALER

Baler B5 Wide

The B5 Wide is characterised by a wide filling opening of 1 metre. It is specially designed to handle bulky materials.

VERTICAL BALER

Baler X10

A compact baler with high capacity and an unmatched 10-tonne press force. Low height and small footprint make it easy to install.

VERTICAL BALER

Baler B20

A flexible baler for cardboard, paper, and soft plastic. A wide filling opening for large boxes and retainers to prevent in-chamber material expansion.

VERTICAL BALER

Baler X25

The X25 is equipped with long stroke cross cylinders for a stable compression and superior press force. Expect a high bale weight.

VERTICAL BALER

Baler X25 Galvanized

Specially developed for wet or demanding environments. Hot-dip galvanized to withstand severe circumstances – indoors or outdoors.

VERTICAL BALER

Baler X30 LP

The X30 LP has a low overall height in combination with a high compaction force.

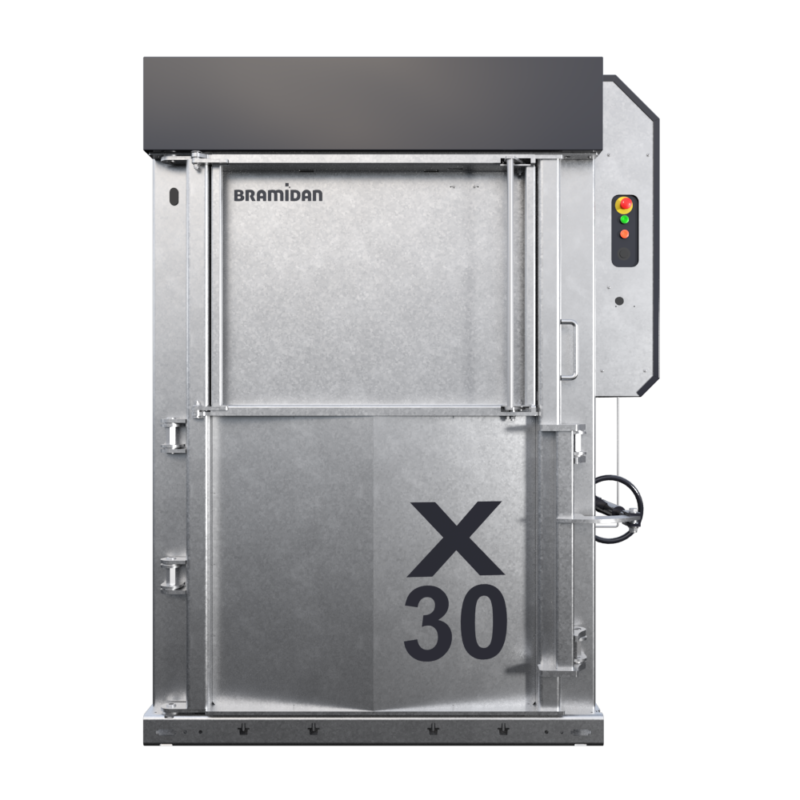

VERTICAL BALER

Baler X30

A baler for many types of materials. Bulky boxes and expandable plastic are no problem for this high capacity and large feed baler.

VERTICAL BALER

Baler X30 Galvanized

Suitable for wet waste or waste with residual liquids. Easy to wash down if needed. Cross cylinder compaction tackles all types of waste material.

VERTICAL BALER

Baler B30 Wide

Enjoy easy loading with the extra wide filling opening. There is no need to fold even large cardboard boxes.

VERTICAL BALER

Baler X40 Wide

The X40 Wide is a low profile baler with a wide filling opening, high press force, and heavy duty construction.

VERTICAL BALER

Baler X50

The X50 is designed for users, who demand a superior heavy-duty machine with focus on operational reliability and safety.

VERTICAL BALER

Baler X50 Galvanized

Our unique range of galvanized balers are designed for wet or demanding environments. Also suitable to be installed outdoors – they can withstand anything the weather throws at them.

VERTICAL BALER

Baler B50 XL SD

The B50 XL with a semi-automatic Sliding Door is an extra-large baler. Enjoy easy loading due to the wide door and deep chamber. Stack bales 2 and 2 for optimal truckloads.