Save money and reduce your CO2e with BRA-IN

Turn waste into value with BRA-IN

Why BRA-IN?

- Connect, monitor, and analyse: A full overview of machine performance and remote service support

- Enhanced waste collection: BRA-IN Optimise lowers your transportation costs and CO2e

- Automated notifications: Receive up-to-date reports and request waste pick-ups.

- Detailed insights: Equipment status, service needs, and more.

Whether you have a single baler or a fleet of recycling equipment, you can explore our various BRA-IN plans below.

“We strive to make a difference in the recycling value chain, enabling sustainable growth for our customers. Our commitment goes beyond providing convenience and saving; it’s about investing in the future of sustainable waste management.

With upcoming regulations such as the Corporate Sustainability Reporting Directive (CSRD) and the global agenda to reduce CO2e emissions, the demand for recycled waste materials is increasing.

This shift underscores that compaction is a strategic investment in the future of sustainable waste managment.

Our dedication to sustainability and innovative solutions empowers our customers to meet these new demands, ensuring a more efficient and sustainable value chain.”

– Henrik Rytter

CCO at Bramidan Group

Intelligent waste management solutions for balers and compactors

Learn more about BRA-IN Connect, BRA-IN Optimize, and BRA-IN Retrofit below.

BRA-IN Connect

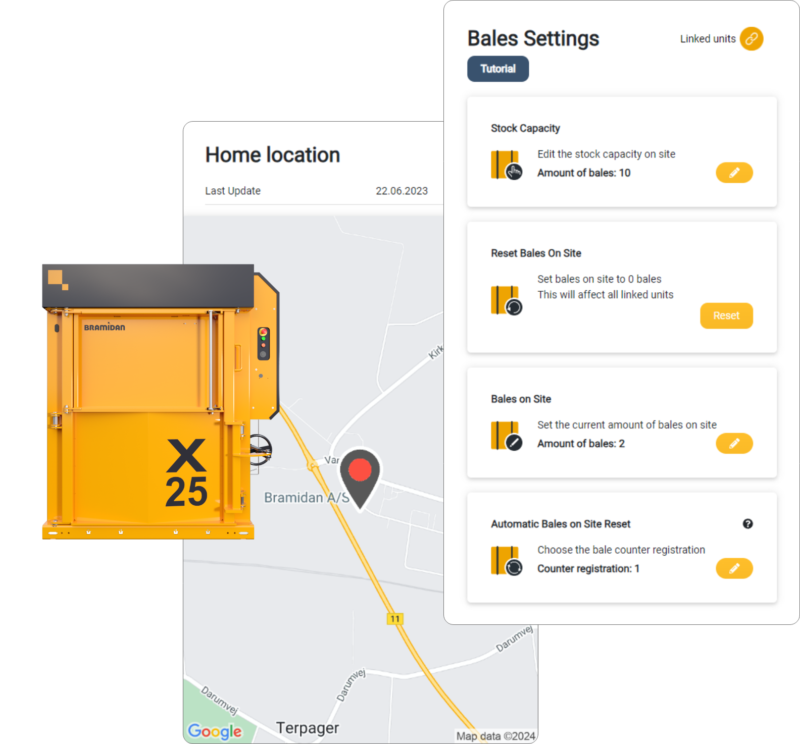

BRA-IN Connect works with all new balers and compactors from Bramidan. With easy access to our BRA-IN portal, you can monitor and manage your equipment digitally.

- Remote service support: Proactive maintenance, remotely checking and adjusting machine settings.

- Automated notifications: Get real-time alerts about your equipment’s status.

- Machine linking: Connect multiple balers into one system for optimised waste collections. BRA-IN notifies you when a preset total is reached.

- Track equipment location: Know where your balers and compactors are at all times.

- Access performance data: View detailed production data, like the number of bales produced.

With BRA-IN, you can link an unlimited number of on-site balers to optimise your waste collection process.

BRA-IN Optimize

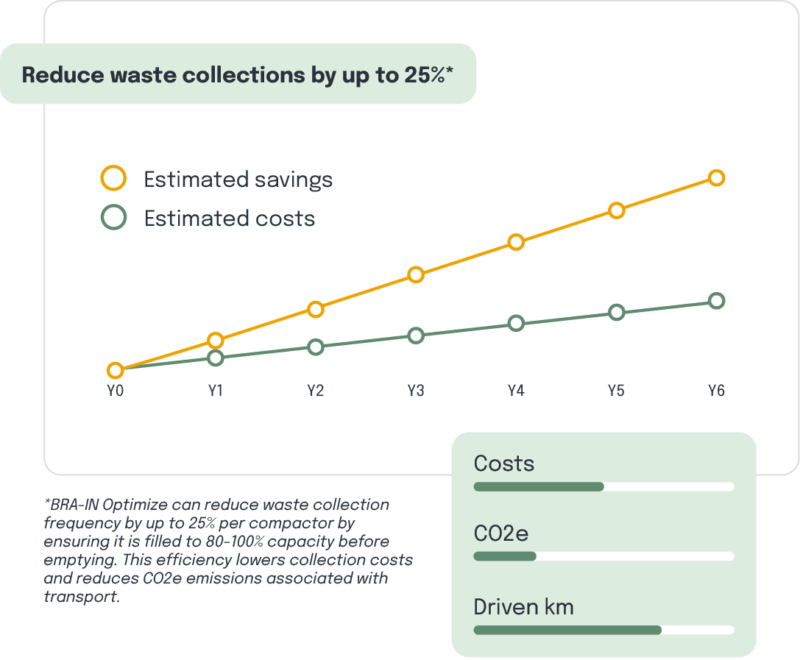

With BRA-IN Optimize, your waste management schedule is automatically communicated to your local waste handler. Meanwhile, our BRA-IN specialists continuously audits your strategy for potential savings while lowering your CO2 footprint.

BRA-IN Optimise reduces the number of waste collections by up to 25% per unit by optimising the fill level of up to 80% before emptying, lowering your transportation costs and related CO2 emissions.

- Monitor and optimise: Our BRA-IN team continually improves your waste collections, ensuring that machines are emptied only when they are over 80% or when strategically appropriate, such as before weekends.

- Fleet management performance: Track machine performance data and easily connect to investigate and adjust settings if the machine is not performing as expected.

- Machine linking: Connect multiple balers into one system for optimised waste pick-ups. BRA-IN notifies you when a preset total is reached.

- Remote service support: Proactive maintenance, remotely checking and adjusting machine settings.

- Automated notifications: Get real-time alerts about your equipment’s status.

- Track equipment location: Know where your balers and compactors are at all times.

- Access performance data: View detailed production data, like the number of bales produced.

Our BRA-IN specialists continuously audit your strategy for potential savings while minimising your environmental footprint.

BRA-IN Retrofit

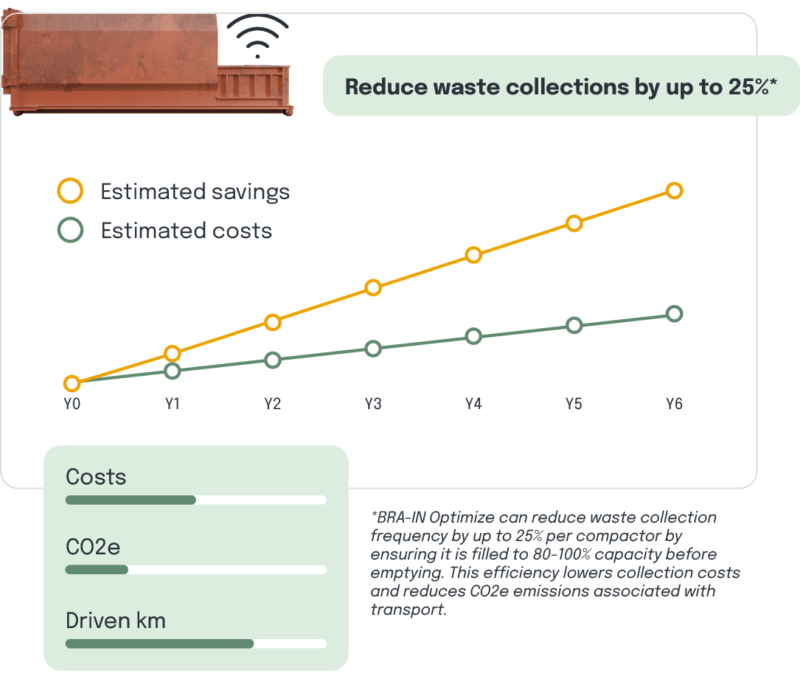

BRA-IN Retrofit allows you to monitor and optimise your older equipment. It establishes an intelligent connection between you, your local waste hauler, and your supportive BRA-IN team.

- Monitor and optimise: Our BRA-IN specialists continually improve your waste collections, ensuring that machines are emptied only when they are over 80% or when strategically appropriate, such as before weekends.

- Fleet management performance: Track machine performance data and easily connect to investigate and adjust settings if the machine is not performing as expected.

- Machine linking: Connect multiple balers into one system for optimised waste collections. BRA-IN notifies you when a preset total is reached.

- Remote service support: Proactive maintenance, remotely checking and adjusting machine settings.

- Automated notifications: Get real-time alerts about your equipment’s status.

- Track equipment location: Know where your balers and compactors are at all times.

- Access performance data: View detailed production data, like the number of bales produced.

With BRA-IN Retrofit, you’re able to upgrade older and third-party equipment to match the functionality of BRA-IN Optimize.

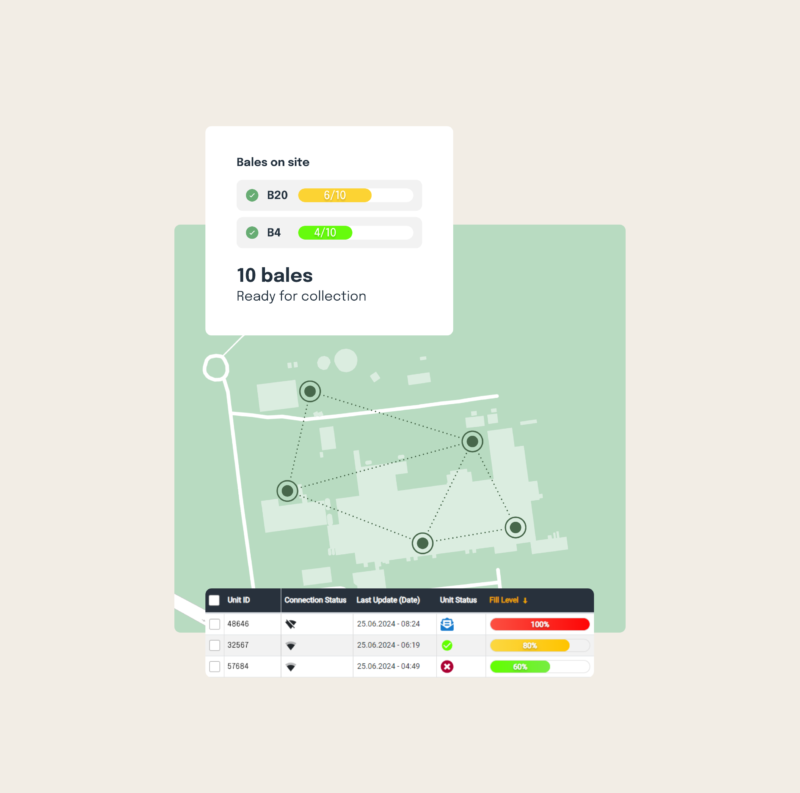

360-degree overview of your recycling equipment fleet

Monitor your entire fleet with the BRA-IN web portal and app. Our accessible digital platforms help you make faster and better decisions, reduce operational costs, and minimise your impact on the environment.

- Remote service support: Easy troubleshooting, extended machine lifespan, reduced repair costs and optimized operations.

- Data collection: Track fill levels, bales ready for collection, equipment errors, and more.

- Machine linking: Connect multiple balers into one system for optimised waste collections. BRA-IN notifies you when a preset total is reached.

- Visualisation: Monitor performance and location of your machines in real-time.

- Interaction: Receive notifications for timely responses to issues, improving efficiency and reliability.

Efficient waste management starts with BRA-IN

BRA-IN

Link

With BRA-IN Link you can control fill levels on 3rd party compactors. Learn from the data to optimise your fill levels, and reduce your cost on transport.

BRA-IN

API

BRA-IN allows you to automatically export data via API, enabling you to monitor machine data and information within your own system whenever and wherever you need it.

BRA-IN

Tracker

Install the sensor to receive notifications when your machine is 80-100% full. Easily connect to the BRA-IN portal to monitor operational status and access reports on usage and fill levels.

Watch BRA-IN Optimize in action

Easy access via desktop and app

With BRA-IN it is easy to manage your waste and recycling activities in one easy-to-use platform which ca be accessed by either web or app.

Performance data is easily accessible either by desktop or mobile app, presented in clear and intuitive dashboards. This insight empowers businesses to make informed decisions, optimise operations, and maximise the efficiency of their waste management.

Webportal

Status of machine

Status of machine: Design the Portal with information relevant to you, such as unit status, site user, motor running hours, days of installation, and much more.

Location of machine: Get full control of where your machines are located. Map pointers give you an overview of your entire fleet, by address or GPS location.Output data: Create reports to show production data from your equipment. Learn how your machine is really used.

BRA-IN App

Status of machine

Access your baler: You can access your baler via QR code on the machine. Within the App you can set up notifications, see instruction manuals, watch videos, and lots more.Notifications: Get full control of the performance of your machine through notifications, directly on your mobile. You can get notifications about finished bales, machine errors, bales ready for collection and more.

Collect finished bales: You can order collection of finished bales to your waste collector – directly from the app. You can even let your machine send an automatic notification to your waste collector.

How to operate: From the app you have direct access to videos about how to operate your machine, instruction- and spare part manuals, and electrical diagrams.

Most common questions & answers

Fill in the form and we will contact you

Questions? Contact us today